Shorten a painful learning curve + SOLUTIONS ADDED

Re: Shorten a painful learning curve + SOLUTIONS ADDED

Before laying this small fastener thread sealing to rest, be aware. It seems BLUE Loctite IS the recommended thread locker. I went to the Fastener Store today prepared to buy BLUE and when I saw it was recommended for 1/4" to 3/4" fasteners -that did not sound right for #6 to #10's to me. Came home with 222MS PURPLE for small fasteners. When I got to the computer, went to the Loctite website and read the stat sheets on BLUE, GREEN and RED. Would suggest y'all take time to do the same before you blue-em-in

Re: Shorten a painful learning curve + SOLUTIONS ADDED

Bet you read instructions and all, doncha?

Some people just like stepping on rakes

Re: Shorten a painful learning curve + SOLUTIONS ADDED

Boo wrote:Bet you read instructions and all, doncha?

DAMN-STRAIGHT after that last fiasco

- yooper_man

- Posts: 777

- Joined: Mon Sep 03, 2012 3:38 pm

- Location: Marquette, MI

Re: Shorten your painful learning curve

TheTinker,TheTinker wrote:This looks like a good pro-active preventative measure.

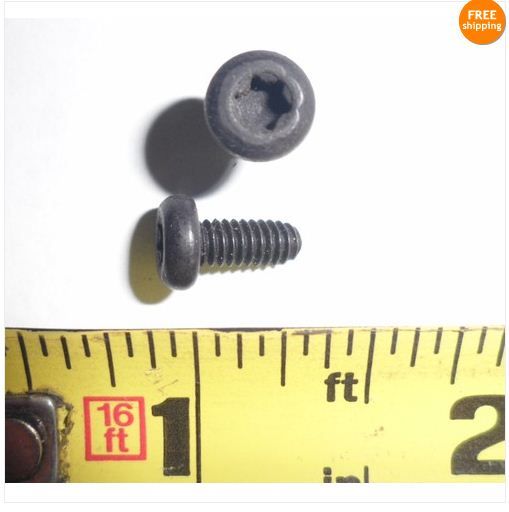

T-20 torx socket in a button socket head 8x32 cap screw. Aircraft grade/black oxide.

http://www.ebay.com/itm/50-ea-8-32-x-3- ... 35bf94bb27

These will require shortening of .025 on the front screws.

'Bet a T-20 torx will not fail you like the puny little Alan hex head does.

Yep, I ordered them ... would pay $14 ANYTIME to avoid several hours of tedious labor like described earlier. Cheap insurance

Cheers, Tink

8-32" is the size for mounting of the scope base? Didn't you oversize your holes and re-tapped them to 10-32" or did you get lucky?

Andrew

2013 Excalibur Matrix 355 Xtra

2007 Leupold VX-I 2-7x33 Dark Earth NWTF Edition Turkey Plex scope

Dan xcaliber flemish Brownell XS2 string, 18" Easton XX75 2219 aluminum shafts, 2" Bohning Blazer vanes, NAP 170gr F.O.C., Danny Miller's RBBB's

2007 Leupold VX-I 2-7x33 Dark Earth NWTF Edition Turkey Plex scope

Dan xcaliber flemish Brownell XS2 string, 18" Easton XX75 2219 aluminum shafts, 2" Bohning Blazer vanes, NAP 170gr F.O.C., Danny Miller's RBBB's

Re: Shorten your painful learning curve

Andrew; I got very "lucky". That was why I was trying to make those who were not aware of the pitfalls more savvy. YES it is still a full set of 8x32's and that is why I was recommending a pro-active approach of replacing the current Alan's with Torx should anyone have the occasion to do so.yooper_man wrote: TheTinker,

8-32" is the size for mounting of the scope base? Didn't you oversize your holes and re-tapped them to 10-32" or did you get lucky?

Andrew

I see from checking the ebay site...

[http://www.ebay.com/itm/50-ea-8-32-x-3- ... 35bf94bb27]

...apparently no one has taken me seriously ...Oh well

Cheers, Tink

- yooper_man

- Posts: 777

- Joined: Mon Sep 03, 2012 3:38 pm

- Location: Marquette, MI

Re: Shorten your painful learning curve

OK, all I can say is you are the man and I thank you for the info.TheTinker wrote:Andrew; I got very "lucky". That was why I was trying to make those who were not aware of the pitfalls more savvy. YES it is still a full set of 8x32's and that is why I was recommending a pro-active approach of replacing the current Alan's with Torx should anyone have the occasion to do so.yooper_man wrote: TheTinker,

8-32 is the size for mounting of the scope base? Didn't you oversize your holes and re-tapped them to 10-32 or did you get lucky?

Andrew

I see from checking the ebay site...

[http://www.ebay.com/itm/50-ea-8-32-x-3- ... 35bf94bb27]

...apparently no one has taken me seriously ...Oh well

Cheers, Tink

I haven't taken off my Equinox scope base, but I heard these come loctite from the factory or are they bare?

Also are they the same 8-32 size as the Matrix?

Andrew

2013 Excalibur Matrix 355 Xtra

2007 Leupold VX-I 2-7x33 Dark Earth NWTF Edition Turkey Plex scope

Dan xcaliber flemish Brownell XS2 string, 18" Easton XX75 2219 aluminum shafts, 2" Bohning Blazer vanes, NAP 170gr F.O.C., Danny Miller's RBBB's

2007 Leupold VX-I 2-7x33 Dark Earth NWTF Edition Turkey Plex scope

Dan xcaliber flemish Brownell XS2 string, 18" Easton XX75 2219 aluminum shafts, 2" Bohning Blazer vanes, NAP 170gr F.O.C., Danny Miller's RBBB's

Re: Shorten your painful learning curve

Welcome! I had no trouble popping the factory set screws loose with the puny Alan. As I recall they were originally locked in. I do not know for a fact but I think they all use the same trigger block so assume they would all be 8-32.yooper_man wrote:

OK, all I can say is you are the man and I thank you for the info.

I haven't taken off my Equinox scope base, but I heard these come loctite from the factory or are they bare?

Also are they the same 8-32 size as the Matrix?

Andrew

From what I learned yesterday, I am afraid to use the BLUE Loctite on this rig. It appears to me that PURPLE (Small Screws) is the one to go with, so I bought some 222 MS Loctite for use on the Excal.

Tink

- yooper_man

- Posts: 777

- Joined: Mon Sep 03, 2012 3:38 pm

- Location: Marquette, MI

Re: Shorten a painful learning curve + SOLUTIONS ADDED

Tink,

I bought the same screws you did and they are awesome.

I trimmed the front 2 screws for the scope base, but I left the rear ones full 3/8" length. I didn't use any loctite on them yet.

I also replaced the Dissipator Bar pad mounting screws with these as well after a little trimming.

Andrew

I bought the same screws you did and they are awesome.

I trimmed the front 2 screws for the scope base, but I left the rear ones full 3/8" length. I didn't use any loctite on them yet.

I also replaced the Dissipator Bar pad mounting screws with these as well after a little trimming.

Andrew

2013 Excalibur Matrix 355 Xtra

2007 Leupold VX-I 2-7x33 Dark Earth NWTF Edition Turkey Plex scope

Dan xcaliber flemish Brownell XS2 string, 18" Easton XX75 2219 aluminum shafts, 2" Bohning Blazer vanes, NAP 170gr F.O.C., Danny Miller's RBBB's

2007 Leupold VX-I 2-7x33 Dark Earth NWTF Edition Turkey Plex scope

Dan xcaliber flemish Brownell XS2 string, 18" Easton XX75 2219 aluminum shafts, 2" Bohning Blazer vanes, NAP 170gr F.O.C., Danny Miller's RBBB's

Re: Shorten a painful learning curve + SOLUTIONS ADDED

What a machinist will try 1st on rounded out holes. Take a small sharp center punch and give it a whack as far out on the diameter as you can.

Then, angle the center punch and give it small taps to unscrew them........works every time.

Then, angle the center punch and give it small taps to unscrew them........works every time.

"Eze 18:21"

Re: Shorten a painful learning curve + SOLUTIONS ADDED

Ive done a few of these. Tried the center-punch like awshucks just explained. That's worked OK on a few. Easy to slip and scratch the rail though, you need to be careful.

The other time I had to drill and tap one out. I was very lucky to get the drill dead center and everything worked out well. Its hard to drill and tap screw that size.

For anyone replacing the screws, remember that any replacement screws need to be the same length. Even a couple of millimeters longer and the trigger latch gets locked in one position so the trigger won't cock/release properly. Check your trigger operation after replacement to be sure.

The other time I had to drill and tap one out. I was very lucky to get the drill dead center and everything worked out well. Its hard to drill and tap screw that size.

For anyone replacing the screws, remember that any replacement screws need to be the same length. Even a couple of millimeters longer and the trigger latch gets locked in one position so the trigger won't cock/release properly. Check your trigger operation after replacement to be sure.

-

flightattendant100

- Posts: 4812

- Joined: Thu Jul 30, 2009 5:06 pm

- Location: Ft. Worth, Texas

Re: Shorten a painful learning curve + SOLUTIONS ADDED

The add for the torx head screws in the above post is for a quantity of 50! Any of you guys that bought some of these want to sell 8 or 12 and recoup some of your outlay? I really dont need 50.

- yooper_man

- Posts: 777

- Joined: Mon Sep 03, 2012 3:38 pm

- Location: Marquette, MI

Re: Shorten a painful learning curve + SOLUTIONS ADDED

Sent you a pm.flightattendant100 wrote:The add for the torx head screws in the above post is for a quantity of 50! Any of you guys that bought some of these want to sell 8 or 12 and recoup some of your outlay? I really dont need 50.

Andrew

2013 Excalibur Matrix 355 Xtra

2007 Leupold VX-I 2-7x33 Dark Earth NWTF Edition Turkey Plex scope

Dan xcaliber flemish Brownell XS2 string, 18" Easton XX75 2219 aluminum shafts, 2" Bohning Blazer vanes, NAP 170gr F.O.C., Danny Miller's RBBB's

2007 Leupold VX-I 2-7x33 Dark Earth NWTF Edition Turkey Plex scope

Dan xcaliber flemish Brownell XS2 string, 18" Easton XX75 2219 aluminum shafts, 2" Bohning Blazer vanes, NAP 170gr F.O.C., Danny Miller's RBBB's

Re: Shorten a painful learning curve + SOLUTIONS ADDED

Ya i could use a set for my 355 if anyone willing to sell some of their spares.

Kandy-a.k.a Raid

Midge- a.k.a Micro 335

SSAS Spynal Tapps-Original

100 Grn 2" Shwacker

Boo threads

Don't wreck the fun house!

Midge- a.k.a Micro 335

SSAS Spynal Tapps-Original

100 Grn 2" Shwacker

Boo threads

Don't wreck the fun house!

Re: Shorten a painful learning curve + SOLUTIONS ADDED

this is what i ended up having to do to get mine out when i changed to the guardian.

i ended up welding the allen key in there and used lock pliers to get it out...

NO DAMAGE WAS DONE TO THE GUARDIAN OR RAIL!

i ended up welding the allen key in there and used lock pliers to get it out...

NO DAMAGE WAS DONE TO THE GUARDIAN OR RAIL!

- NEPAbowhunter

- Posts: 524

- Joined: Fri Aug 17, 2012 1:15 pm

- Location: Steamtown, PA.

Re: Shorten a painful learning curve + SOLUTIONS ADDED

Just ordered the torx screws. Thanks!

Matrix 355

Bulldog 380

Mission Sub-1

https://www.youtube.com/watch?v=bS9N8dEdZCQ

Bulldog 380

Mission Sub-1

https://www.youtube.com/watch?v=bS9N8dEdZCQ